Key Takeaways:

- Selecting The Best 3D Printer: Learn how to pick the right 3D printer for your cosplay, movie replicas, or set designs.

- The Use of Different Filaments: Learn how the use of different filaments, such as PLA, ABS, and PETG, can affect your props’ strength, pliability, and aesthetic qualities.

- Post Processing Techniques: Understand the process of smoothening, painting, and assembling 3D printed props for a polished look.

- New Trends and Tools: Analyze the trends and tools which are currently changing the landscape of 3D prop making.

- Practical Approaches to the Most Common Problems: Learn actionable strategies for dealing with costs, the learning curve, and material prop creation constraints.

Introduction: The Benefits of 3D Printing for Prop Makers

Introduction: The Benefits of 3D Printing for Prop Makers

Imagine the ability to design a customized prop for your cosplay, film set, or artwork, and not needing to use the costly and tedious traditional methods. That could be possible with a 3D printer. Whether you are a seasoned prop maker or a novice, prop 3D printing offers a high level of accuracy, saves time, and design flexibility. In 3D printing, the choice of 3D modelling software influences the precision of the project.

This guide will lead you through the processes involved in using a 3D printer for prop making, including choosing a suitable machine, the relevant materials, and the necessary post-processing techniques. Let’s get started!

What is a 3D Printer for Props?

Defining 3D Printing in Prop Making

In prop making, 3D printing—sometimes referred to as additive manufacturing—encompasses the layering of materials, including plastics, metals, and resins, to construct an object. One of the benefits in the context of prop making is the ability to manufacture intricate designs directly from files, making the process significantly easier.

3D printing allows for a wide range of prop designs, from keychains and toys to intricate pieces such as movie-quality armour and meticulously crafted weapons. One of the most significant advantages of 3D printing in prop making is its ability to streamline the process of bringing a creative concept to life with great accuracy.

Real World Example: Let’s say you are an actor in a fantasy movie and you need a custom sword. Instead of manually carving the sword, which can be a costly and time-consuming process, you can design it on a computer and print it out.

The Impact of 3D Printing Technology on Prop Making

With the newfound accessibility of 3D printers, the prop industry for cosplay, film, and even theatrical performances is undergoing a significant transformation. The time and cost efficiency provided by 3D printers allows for the production of immense detail and precision in props. Whether you are a hobbyist making cosplay props for a Comic-Con or a 3D novice working on a Hollywood movie set, you can manufacture props with intricate details using 3D printing technology.

Advantages of 3D Printers in Prop Making

Cost-Effective Production

One of the most significant advances of 3D printers is the reduction in cost compared to traditional methods. The prop industry is notorious for spending substantial amounts of money on buying sophisticated equipment, materials, and labour; all these are minimised with the help of 3D printers.

Example: A perfect example of this is the prop project with the set of gauntlets. Using traditional means, you would spend labour and materials amounting to hundreds. However, using a 3D printer, you would only pay $50 to $60 in materials and filament for the gauntlets.

Tailored Orders and Accuracy

Extreme tailoring provided by 3D printers makes the manufacturing of props easier. No longer will the prop makers be restrained by traditional ways of producing intricate and detailed movie replicas and costumes, as 3D printers remove that restriction.

For instance, when constructing a famous superhero’s helmet, there is no need to mould or sculpt as with traditional methods, so that you can achieve the desired shape and intricacies with 3D printing with ease.

Case Study: The prop makers for the Avengers movies relied on 3D printing to accurately replicate the helmets, armour, and weapons, which would have required intensive work using older methods.

Time Efficiency

The time it takes to produce elaborate props is significantly reduced. Strenuous work that required weeks of effort can now be completed in days. For a prop designer, there is no longer a need to experiment for a long time. For instance, with 3D printing, multiple versions can be made within a matter of hours instead of several days with traditional casting and moulding methods.

Selecting a 3D Printer for Effective Prop Creation

Essential Considerations

When looking for a 3D printer for props, there are a few key features that improve the quality of the work and smooth the workflow:

- Build Volume: Allows for scaling up props and multicomponent prints for larger props. A larger build volume would be best for large props such as swords and armour.

- Print Quality: Higher resolution ensures finer details. It is significant for intricate designs, such as weapon replicas or detailed helmets.

- Supported Materials: There are different types of 3D printers based on the materials. Make sure the printer you want to purchase can support the materials you want to work on.

Best 3D Printers for Props in 2025

Purchasing decisively depends on the budget and the type of prop. One can consider:

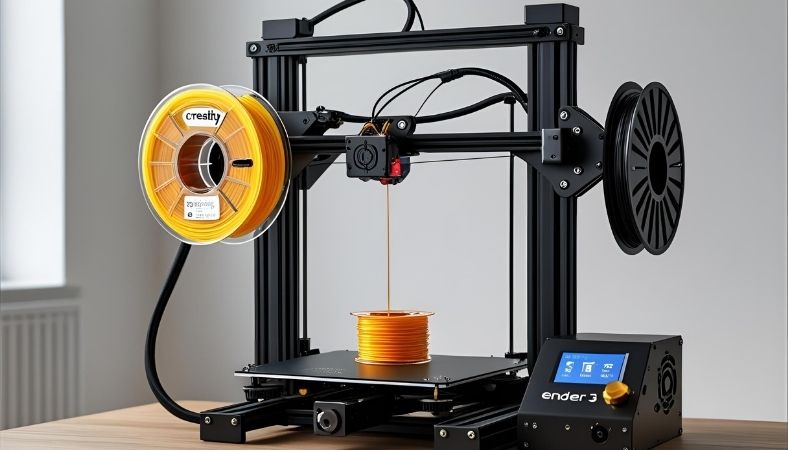

- Printer brand: Creality

- Printer model: Ender 3 (V2)

- Price: Budget Friendly

- Pros: Great for beginners, large print size, and reliable

- Cons: Limited material options

Best For: Cosplay and small prop projects.

Prusa i3 MK3S+

- Price Status: Mid-range

- Benefits: High accuracy, user-friendly, broad application

- Drawbacks: High cost relative to the market

- Optimal Output: High-end professional fibreglass parts and highly detailed fibreglass parts.

Anycubic Photon Mono X

- Price Status: Less expensive than market

- Benefits: Sharp details, quick throughput

- Drawbacks: Smaller overall dimensions

- Optimal Output: Small, highly detailed props.

Best Filaments For Prop Makers

Selecting the proper filament will determine the physical and aesthetic properties of your prop. The following sections summarize the best fillaments:

- PLA (polylactic acid): It is inexpensive and works well in prop making. Easy to print in different colours.

- ABS (Acrylonitrile Butadiene Styrene): Stronger than PLA because it handles heat better, which is critical for props that suffer rough handling.

- PETG (Polyethene Terephthalate Glycol): Strong, flexible, and resistant to heat, it is a combination of the two classes of filaments: PLA and ABS.

- TPU (Thermoplastic Polyurethane): Flexible and rubbery, suitable for props that need to be flexible, armour and other wearable props.

Materials for 3D Printed Props: What to Choose?

Materials for 3D Printed Props: What to Choose?

Common 3D Printing Filaments

3D printing has permeated various industries, with props being one of the easier categories to break into. Even though props can be created using a variety of materials, PLA and ABS are among the most popular and best-selling. When applied to lightweight props, PLA can be a good option, as it is relatively easy to work with. ABS is the go-to choice for durable and heat-wielding props.

PETG is another popular choice because it combines the best qualities of both PLA and ABS. It is more durable and flexible than PLA, making it an excellent option for large, functional props.

Advanced Filament Options for Unique Props

If you’re aiming for a more professional or high-end look, composite filaments infused with carbon fibre or metal filaments should be considered. Beyond just looks, with these materials, you can add texture or increase the strength and polish of your props.

Using carbon fibre-infused filaments can yield props that are both durable and lightweight. These lightweight filaments are excellent for cosplay or movie sets.

Post-Processing Techniques for 3D Printed Props

Sanding and Smoothing

Post-processing is the follow-up step to 3D printing. Primary finishing involves sanding and smoothing, and for PLA-based props, gentle heat smoothing can be very effective for polish and shine.

Painting and Detailing

Now that you have completed the sanding stage, you can move on to inserting colours as well as the finishing touches. For large props, the most efficient method is to use a spray-painting technique. Detail work, such as weathering and some metallics, can be accomplished using acrylics. Remember to add a seal coat to minimise chipping on the paint.

Professional Hint: To avoid uneven finishes and drips, use several thin layers of paint as opposed to a single thick layer.

Assembly and Finishing

If some props are too large to 3D print in one piece, they can be printed individually. Each piece can be joined using super glue, epoxy, or screws. When joining the pieces, remember to keep the structural integrity in mind. Make sure that the pieces are well secured with each other and aligned to maintain a seamless appearance.

Common Challenges and How to Overcome Them

The Cost and Investment in Equipment

For some people, the price of a 3D printer may seem too high. But in the long run, the amount you will save in labor, and materials will far exceed the initial price. If you are on a budget, you can always start with a mid-range printer such as the Creality Ender 3 that is well known for offering good value for its price.

Learning Curve and Skill Development

3D printing offers remarkable capabilities, but like most powerful tools, there is a learning curve associated with it. For optimal results, learning 3D modelling software like Blender or Tinkercad is essential. There are numerous tutorials online, and with time, practising will enhance your speed and efficiency.

Material Limitations

Some props may require specific types of filaments. For instance, PLA works well with some lightweight items, but it is not heat-tolerant. For props that will take heat or heavy use, ABS or PETG would be a better choice.

Conclusion: Begin 3D Printing for your Props

3D printing has changed the process of making props, enhancing the level of customization achievable, precision during the design, and lowering the cost by a significant margin. Whether you are designing a cosplay costume or a set piece for a film, with the right 3D printer and materials, you can bring your idea to reality.

If you are a beginner, buy a 3D printer and play with the filaments and techniques, you will figure out a lot on your own. And of course, do not be disheartened if you are not perfect on your first few tries; do remember, practice is the key. Continue learning, and you’ll be designing great-looking props that would be the envy of many professionals.