Key Takeaways:

What is a 3D printing machine? Understand what 3D printing is and the different types of machines that can be used for different purposes.

- Transforming Industries: Explore the benefits of 3D printing on healthcare, manufacturing, education, and other industries.

- 3D printing: Understand the cost-saving, creativity-driving benefits of 3D printing, as well as the challenges posed by steep initial investment.

- Selecting your 3D Printer: Explore the critical factors that we consider before you make your purchase.

- Emerging trends: Stay ahead of the curve with the integration of AI and green materials.

What is a 3D Printing Machine?

What is a 3D Printing Machine?

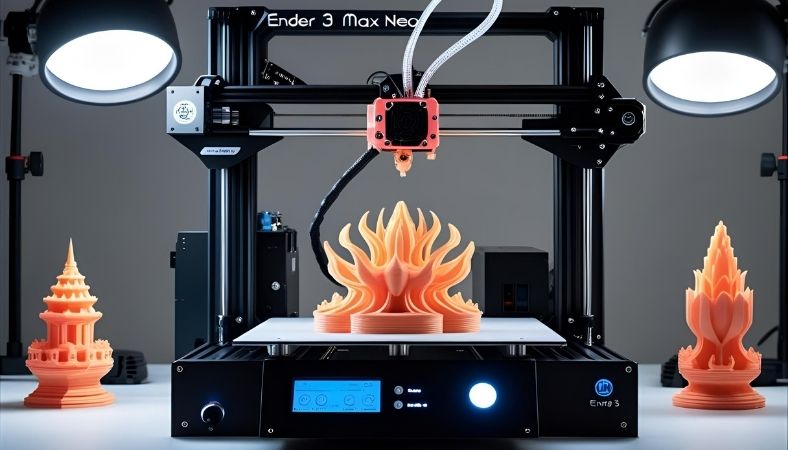

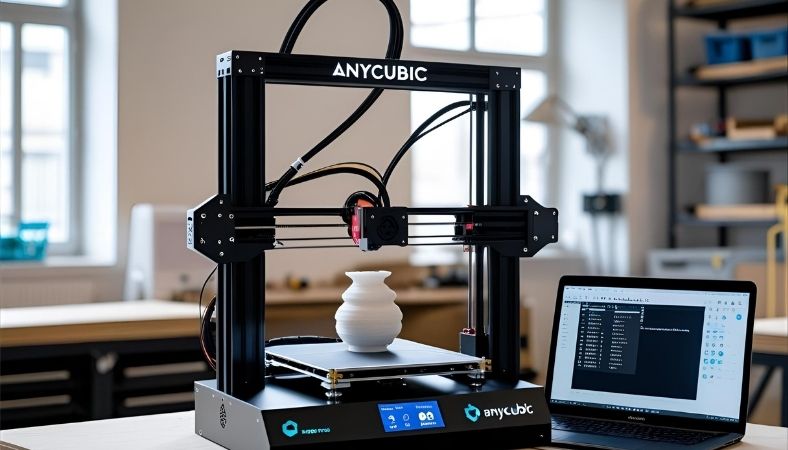

3D printing, or additive manufacturing, is a technique of creating a physical object by adding material layer by layer. It is the exact opposite of conventional manufacturing, where materials are shaped or cut into parts. In contrast, a 3D printer adds to the base part to build the object, which gives it a lot of flexibility. Get your Anycubic printer operational in Cura, even if it lacks out-of-the-box integration.

There are different types of machines for 3D printing, such as FDM, SLA, and SLS, which serve different purposes. Each of these types has benefits depending on the use case, materials required, and even the budget.

Categories of 3D Printing Equipment

- FDM (Fused Deposition Modeling): This is the cheapest and most popular 3D printer type, perfect for home use. FDM printers utilize plastic filament, which is melted and shaped into layers, to construct objects.

- SLA (Stereolithography): SLA printers specialize in creating very detailed objects. Jewelry and dental work are particularly SLA dominated. The printers utilize light to solidify layers of liquid resin for construction.

- SLS (Selective Laser Sintering): SLS is incredibly precise and durable. The construction equipment uses lasers to solidify powdered materials into precise and durable structures. Industrial applications for SLS are very common, as long-lasting parts are often needed.

Main Functions of 3D Printing Equipment

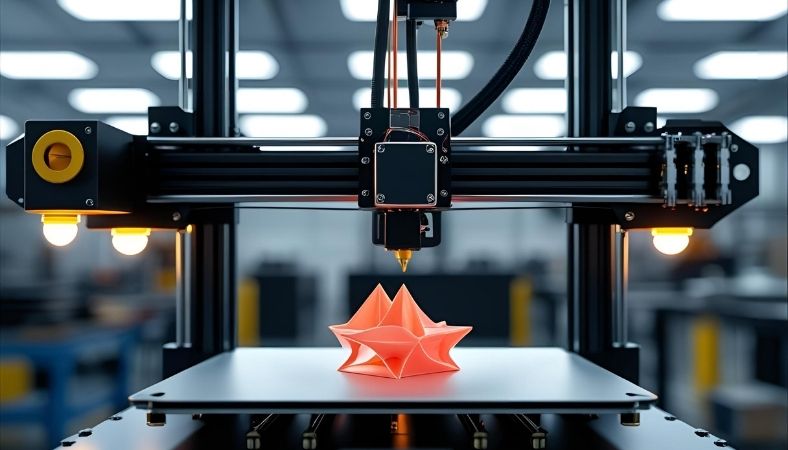

3D printers are no longer just for hobbyists. Various industries have found practical uses for the devices, making them useful in enhancing productivity, designing new products, and making them cheaper. Here’s the breakdown of its uses:

Printing in the Manufacturing Sector

3D printers have added a new dimension to the work of manufacturers. Companies are now able to design and print prototypes much faster and at a lower cost. Tesla, for example, uses 3D printing to manufacture specific parts for its vehicles, saving a lot of time and resources.

Real world example: Imagine a toy company that could come up with designs for new toys, print them, and have prototypes ready within hours instead of waiting many weeks as is the norm with traditional molds.

Healthcare Utilizing 3D Printing

3D printing has rapidly evolved and is now being used in the healthcare field. It helps doctors make specialized surgically fitted parts of the body known as prosthetics and even implants. With prosthetics being manufactured specifically for the individual’s requirements and dimensions, they can stream line comfort and functionality significantly.

Case study: Scientists have also been able to create bioprinted organs for research, which helps to address the organ shortage problem.

Education Utilizing 3D Printing

3D Printing will harness the potential of students in the classroom to encourage the creativity flow while also teaching them the practicality of learning. Students can use 3D printers in school to develop and create models which in turn boost their learning in various subjects such as geometry, engineering, and biology.

Example: A middle school class could learn architecture and history by designing 3D models of historical landmarks.

The advantages of having access to modern 3D printing machines

3D printing offers multiple advantages to individuals and businesses. It is not just a fancy piece of technology in the workshop.

Saving money in the designing and production phase of the business.

The single most important benefit of 3D printing is the significant saving in the designing and prototypinging stages of production. Old techniques, which used to be employed, like injection molding, were expensive and extremely slow. Compared to this, 3D printing is much quicker and far more cost-effective.

Example from the World: Businesses can now print out prototypes instead of using expensive molds and tools and can print them out in mere hours.

Customization and Personalization

3D Printing helps in personalizing jewelry and prosthetic body parts. The whole concept of 3D printing means that if you dream it, you can create it.

Example: Custom phone cases can now be designed and printed according to personal preference and can be fully personalized using a 3D printer.

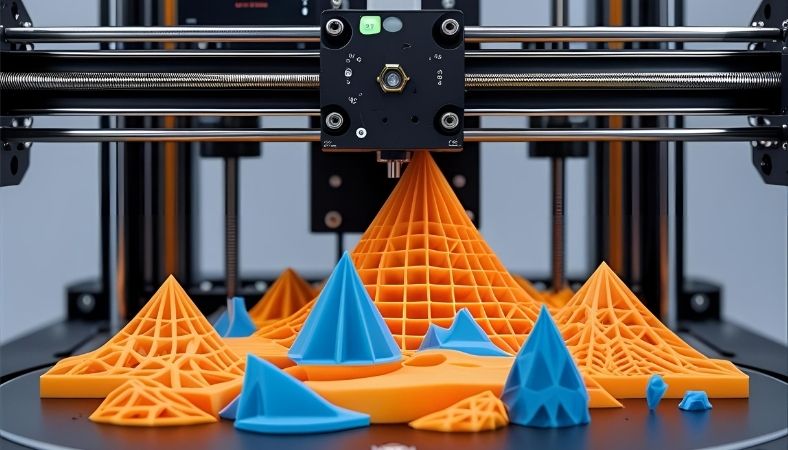

Innovation in Design

With 3D Printing, you can now break the limits of traditional manufacturing and create intricate geometries and designs that cannot be achieved using traditional methods.

Case Study: More advanced and complex geometries have been adopted in the aerospace industry to manufacture lighter parts to make the parts more fuel-efficient.

Sustainable Practices

Unlike traditional methods, 3D Printing can be more environmentally friendly. The use of PLA helps reduce plastic waste making 3D Printers more Eco friendly. Furthermore, 3D printing allows the manufacturers to create parts that are needed and helps reduce the material that is thrown away.

Example from the World: Eco homes can now be printed and are budget friendly. The plastic used in printing these homes can be recycled, which reduces waste.

Obstacles and Issue Areas of 3D Printing Machines

Obstacles and Issue Areas of 3D Printing Machines

3D printing technology has its obstacles and problems to tackle, just like its advantages.

High Initial Investment

The initial cost always becomes the primary challenge for adopting 3D printing technology. Investing into industrial grade 3D printers can run into the hundreds with no return for smaller businesses and individuals.

Solution: Try starting with entry level 3D printers, like the Creality Ender 3 which is very cost-effective for its pricing and offers amazing value for the money.

Steep Learning Curve

3D printing is very simple for some people, but, very complex for beginners to grasp the technology. The printing process itself has several steps, which include setting up the printer, selecting the materials, and customizing the prints.

Practical tips: Start with entry-level machines paired with online guides. Be persistent and you will get the most out of 3D printing technology.

Maintenance and Durability Concerns

3D printers now undergo streamlining and require maintenance to operate with optimal efficiency. For new users, the most common problems of clogged nozzles and misalignment of the print beds can lead to loss of motivation.

Expert advice: Ensure to always do maintenance checks on the 3D printers regularly and clean out the extruder, and do print bed calibration before every print job.

Limitations in Materials

Not every material can be used in 3D printing. Some materials are too weak, while others are too dense. There is a rather narrow selection of materials, which can be stifling.

Solution: Experiment with different materials to find the most suitable for your design. Several types of 3D printers are able to work with materials such as PLA, ABS, and even Nylon.

How to Pick the Right 3D Printing Machine

Navigating the market can be easy with the right guidance. Consider these several points before making a decision:

Printing’s Precision and Quality

A printer with high-quality, detailed, vivid color printing should be prioritized. While high quality detailed prints will be a plus, they will increase printing time.

User Friendliness

It is best to go for a printer that is simple to use and set up. Beginner 3D printers are often sold as high quality kits with easy to follow instructions.

Compatibility with Materials

Make sure that the 3D printer you settle for is not restricted with the kind of materials you are planning to use. If for example your prints will be jewelry, your printer should be able to use resin or high-precision filaments.

Budget

Set a budget first. You can find entry-level printers starting at $200. Industrial printers, however, are more expensive, sometimes reaching thousands of dollars. Remember to factor the purchase price alongside ongoing costs.

Future Trends in 3D Printing Machines

As the 3D printing field develops, it brings some trends that should be noted.

AI-Driven 3D Printers

AI adoption is on the rise, bringing 3D printing technologies to a new level in speed, accuracy, and overall effectiveness. During printing, AI can modify the print in real-time, automatically changing the print parameters to get a better print, thus saving time and materials.

Eco-Friendly Materials

There is a higher focus on sustainability when it comes to 3D printing, which in turn, brings more biodegradable and recycled filament options. This change can make 3D printing machines more environmentally friendly.

Large-Scale 3D Printing

The adoption of large-scale 3D printers is gaining traction, especially in construction. You can envision 3D printing entire homes or even buildings. This will dramatically change the future of housing.

Conclusion: Is 3D Printing Right for You?

3D printing machines can be useful for manufacturing at an industrial scale, developing prototypes, or even personalizing items. In spite of having some challenges, the distinct advantages, especially when the correct approach is taken, make 3D printing machines incredibly useful.

Website: For those wishing to delve into the 3D machine printing world, it is recommended to start with an entry level printer. By doing so, you make it simpler to adapt to 3D printing and with time, you can transition to more advanced and even industrial models.

- Intro: For the rest of this reading we will formulate answers to some of the most common questions concerning 3D printing machines.

- Intro: Prices of 3D printers can differ to a significant extent depending on the machine. Feature and intended purpose can make an even entry level printer cost 200$, while more feature rich models can go upto 5000$.

- Intro: 3D printing machines are devices that build items using technology for layering material like FDM, SLA or SLS. The machines take a digital design and, in a base-to-top approach, construct an object.

Frequently Asked Questions

Can I use my phone for 3D printing?

Direct 3D printing from a phone isn’t possible, but some apps let you create 3D models or control a 3D printer. A computer or dedicated software is needed for the actual printing.

How about selling 3D prints?

Selling 3D prints can be done legally, but pay attention to copyrights. It is important to check that the designs are original, or that you have the rights to use and sell those made by other people.

What are the materials for 3D printing?

3D printing technologies use materials such as PLA, ABS, Nylon, and Resin. Every material has its usefulness depending on its flexibility, strength, detail, and other unique characteristics.

Does 3D printing require a lot of effort?

3D printing isn’t especially challenging, but it is a problem for beginners working on the configuration. Over time, you’ll learn the common problems and how to resolve them, and you’ll be able to make solid prints.