Anycubic photon mono x2 review for beginners

If you are a newcomer to the 3D printing community, you are most likely in search of a printer that is user-friendly, prints to a high standard, and performs reliably. Look no further than the Anycubic Photon Mono X2. This outstanding resin printer stands out for its fantastic features and forgiving approach to design. With a plethora of options currently on the market, is the Mono X2 the right choice for you? Let’s conduct an in-depth review to aid in that decision. The 3D printing industry is now easier to penetrate, and the adoption of the technology is much broader.

Key Takeaways:

- Easy Setup for Beginners: Due to its intuitive design, the Photon Mono X2’s setup is effortless. It can be tackled by neophytes in the field of 3D printing.

- Impressive Print Quality: The printer’s 4K+ resolution, combined with its expansive build volume, allows for the reproduction of intricate and precise prints.

- Troubleshooting Made Simple: In the guide, we will address the most common problems of misalignment and resin adhesion and provide solutions.

- Maintenance Tips: The printer can be preserved for years by adopting basic and efficient strategies.

- Comparisons with Competitors: An analysis of the most popular 3D printers, Mars 3 and Halot-One by Creality, will be conducted with the Photon Mono X2.

Introduction: What Makes The Anycubic Photon Mono X2 Stand Out?

Anycubic Photon Mono X2 is a renowned printer that is geared towards beginners. Ideally, your first 3D printer should be easy to use, set up, and troubleshoot, and deliver reliable prints. The Anycubic Photon Mono X2 is an affordable printer that offers a wealth of user-friendly features. But does it deliver on its promises?

This guide is aimed at answering all your questions, starting with an unboxing to resolving the most common issues. I hope to equip you with the right amount of knowledge to make an informed decision regarding your purchase; therefore, let’s dive in.

Setting Up The Anycubic Photon Mono X2

Unboxing and Initial Thoughts

The printer, a build plate, a resin tank, and a few extra items are all located within the box, and this is the user’s first impression of a 3D printer. The manual is highly detailed, easy to comprehend, and the entire setup is a walk in the park. The simplicity of the setup is going to be a breath of fresh air for many people who have dealt with convoluted and complicated setups.

Your Step-by-Step Guide To Setting Up

- Attach the Build Plate: Start by sliding the Z-axis with the build plate attached into the holder and tightening the predetermined screws.

- Fix The Resin Tank: The next step is to fix the resin tank by placing it right into its slot ensuring a tight fit.

- Printable Area Leveling: While it is necessary to perform manual leveling, it is straightforward. The process is displayed on the printer screen, making it beginner-friendly for absolute novices.

- Loading the Resin: Ensure the resin is loaded into the tank properly. It is an optimal time to check that the printer is properly prepared.

While the Photon Mono X2 lacks features for automated bed leveling, its manual counterpart is friendly for beginners.

Performance and Quality of Prints

Accuracy and Resolution of Prints

Print resolution is always one of the most notable features of a Photon Mono X2, and it is at 4096 x 2560, which is 4k; thus, it has a 4K+ LCD. Such resolution means that printed objects can have outstanding details. Regardless of whether it is a design, a figurine, or a miniature, the machine will consistently deliver with high resolution and precision.

Let’s explain more:

- The XY Precision: The X2 offers 48μm precision, complemented by a layer of details, making it highly competitive with high-priced devices.

- Z-Axis Precision: The printed accuracy on the vertical axis improves with dual linear rails, which provide more stability and make movement smoother, thus avoiding warping errors with prints.

Speed vs Quality

The Photon Mono X2 exhibits an ideal convergence of speed and quality. Efficiency is maintained alongside detail with a speed of 2.36 inches per hour. This is particularly beneficial for users who wish for multiple prints in a short amount of time.

Printing a small figurine, for instance, would take approximately three to four hours. A larger figurine would take close to eight hours. Even though these are reasonably fast, they are still consistent, and if the settings are proper, the layer lines will be minimal.

Troubleshooting Common Issues

Layer Issues and Misalignment

Misalignment is an issue that many users of a resin printer will come across at some point. In the case that the initial few layers look to be misaligned, there is a chance that the printer’s bed is miscalibrated. Good news is that this is a simple problem to solve. The leveling of the bed can be fixed by confirming that the build plate is perfectly parallel to the resin tank.

Pro Tip: A method where you slide a piece of paper into the gap between the build plate and the screen, only to pull it back. If the paper encounters some resistance, then your bed is perfectly leveled.

Problems with Adhesive Resins

Another issue with resin printers is the failure of the resin to adhere to the build plate. This often occurs due to the build plate surface not being cleaned thoroughly or due to the use of incompatible resin.

Solution: The build plate should be cleaned thoroughly with the appropriate cleaning solvent and washed with water after each use to foster correct adhesion. In addition to cleaning, the use of adhesion aids, such as applicable print surfaces and specially formulated resins, is beneficial.

Best Maintenance Practices

Daily and Weekly Maintenance

- Daily: Each print should be followed by cleaning the resin tank and the build plate. This reduces the chances of cured resin building up and negatively affecting print accuracy.

- Weekly: Gently wipe the entire printer and inspect the FEP film within the resin tank for any mounting wear. In the presence of such wear, the FEP film should be replaced regularly to prevent the printer from leaking during operation.

Long-Term Care

- Replace FEP film regularly: FEP film is the layer that separates the resin from the LCD screen. This film may develop scratches or cloudiness due to aging, leading to deterioration of print quality.

- Lubricate the Z-axis: The Z-axis rail should be regularly lubricated to ensure its rotational motions remain smooth and free from wear.

Tips for Handling and Storing Resin

For optimal results, 3D prints should be processed and printed with the proper materials, including resin. For best results, the resin should be stored in a cool and dry location, away from sunlight exposure, heat, and moisture. The cap should also be tightly sealed to prevent any form of resin contamination.

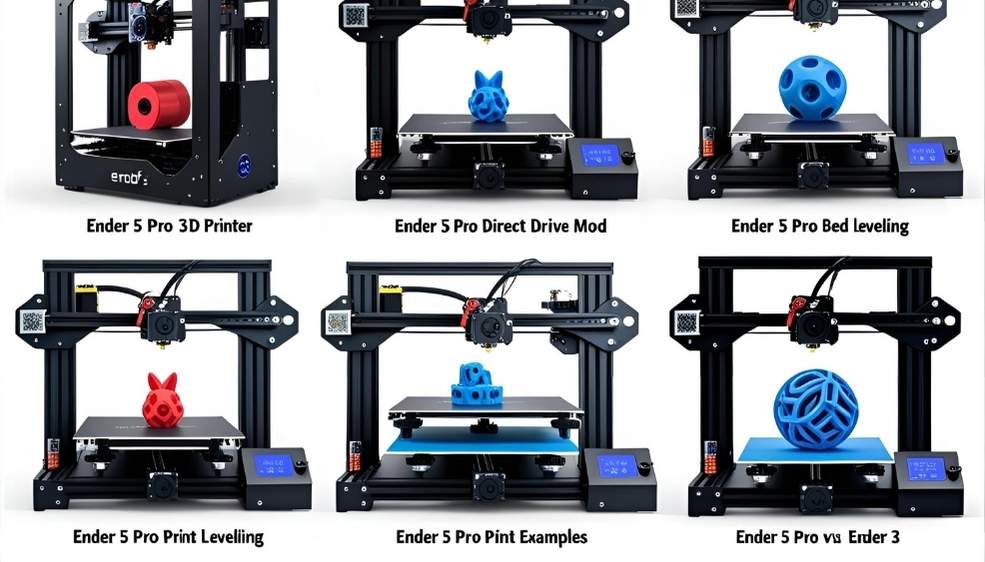

Comparing the Anycubic Photon Mono X2 with Competitors

Photon Mono X2 vs. Elegoo Mars 3

Both Photon Mono X2 and Elegoo Mars 3 are equipped with 4K resolution 3D printers. However, the Photon model takes the lead with a larger build volume of 200 x 196 x 122mm compared to the Mars 3’s 143 x 89 x 175mm. The X2 remains the better choice for those who need to print larger models. The Elegoo Mars 3 outperformed the Photon X2 in print speed and is more ideal for time-sensitive projects.

Photon Mono X2 vs. Creality Halot-One

Another X2 competitor is the Halot-One, which is popular for its cost-effectiveness. However, the X2 wins in terms of detail and precision. Its 48μm XY precision is superior to the 72μm of the Halot-One. The Creality printer has the advantage of a larger display, 7.9 inches compared to the 6.1 inches of the Photon X2. This makes the Halot-One better for bulk prints. Expert Advice and Additional Strategies

Achieving Optimal Results

Slicing software: Chitubox is powerful and versatile slicing software, especially for the Photon Mono X2. Chitubox has features that allow you to tailor every aspect of the print for better outcomes, which leads to consistent print quality in the long run.

Best printing practices: For detailed prints, it is advisable to use thinner layers of around 0.05mm to 0.03mm. While you can use thicker layers to increase speed, this will come at the cost of details on the print.

Selecting the Appropriate Resin

The Photon Mono X2 is compatible with many types of resins, though Anycubic’s own brand tends to work best. If you are printing miniatures and models with many details, use specialized high-detail resins which ensure finer layer precision.

Frequently Asked Questions

Is the Anycubic Photon Mono X2 beginner-friendly?

Absolutely! The X2 focuses on functionality and ease of use. The mini 3D printer’s step-by-step guide makes it easier to use the X2. The printer’s setup takes almost no time and is complemented with an intuitive touchscreen interface.

What is the estimated lifespan of the Anycubic Photon Mono X2?

The estimated lifespan of the Photon Mono X2, when properly maintained, can reach several years. As is the case with any other printer, routine cleaning, FEP film changes, and Z-axis adjustments help maintain the printer’s functionality.

What is the best resin for the Anycubic Photon Mono X2?

For everyday purposes, Anycubic Photon resin works well. For more intricate models, perhaps look into Anycubic’s plant-based resins or other high-detail third-party resins.

Conclusion: Should You Buy the Anycubic Photon Mono X2?

For those who are new to 3D printing, the Photon Mono X2 is exceptionally priced. For newcomers, it is simple to assemble, has numerous useful features, and produces excellent prints. The printer works exceptionally well for printing miniatures and small components, delivering remarkable speed and accuracy.

Try 3D Resin Printing Today

Want to get started? The Photon Mono X2 will have you printing high-quality models in no time. Test it for yourself and discover the sophisticated possibilities resin printing has in store for your next project!