Key Points:

- Identify the best 3d printer for helmets, including leading models, materials, and technologies such as FDM and SLA.

- Learn to select a printer suitable for the type of helmet you are making (cosplay, motorcycle, safety).

- Learn the main issues associated with helmet 3D printing and study practical solutions for them.

- Learn practical techniques for the helmet’s final finishing steps, maintaining its strength and quality.

- Learn how to achieve the best results with ease during printer use and reduce costs from professionals.

The Best 3D Printers for Helmets: Your Ultimate Guide

The Best 3D Printers for Helmets: Your Ultimate Guide

The 3D printing industry continues to grow and improve, just as the number of areas it covers and the tools it creates, including models and tools, such as helmets, have also been printed with FDM and SLA technology. As a dedicated cosplayer, motorsport aficionado, or someone seeking precision in a bespoke item, understanding the best 3D printer for helmets is integral to ensuring efficiency and quality in their use.

But with all the options available, how do you determine which printer best matches your requirements? This article addresses all the essential details concerning 3D printing helmets, such as the top printers and materials, frequent difficulties, and expert advice for perfecting your designs. So, let’s dive in!

Optimal Reasons for 3D Helmets

There are numerous benefits as to why 3D printing has become the preferred method of production for helmets. Unlike older methods, which incorporated very costly moulds, 3D printing allows for the rapid creation of very detailed helmets at a far lower price. This flexibility to manufacture helmets in small volumes, even from the comfort of your home, increases creativity and reduces waste.

Customization is not the only benefit offered. 3D printers can design highly durable and lightweight helmets that can be worn daily, for cosplay and motorsports. With the right materials, it’s possible to maintain a perfect balance between aesthetics and durability.

Key factors to keep in mind when buying a 3D printer for helmets

As with every purchase decision, there are always some factors that may make or break a project, and a printer is no exception. H3 outlined below are project settings that make a difference when deciding to print helmets.

Print size and resolution

For an effective workflow when printing helmets, the space available on the printer is a factor to consider. A 3D printer needs an adequate print size for the helmet to be printed as a single part. Some printers are designed with large build areas and make helmet printing easier, while others may require you to print in sections and assemble them later.

Resolution is another key factor. For helmets, you want a high level of detail, especially if you’re incorporating intricate designs like faceplates or vents. A printer with a higher resolution will produce smoother, more detailed prints.

Material compatibility

The material you choose will significantly affect the durability and finish of your helmet. Here are the most common materials used in 3D printing helmets:

- PLA: Ideal for beginners, it’s easy to work with and produces smooth finishes. However, it’s not the most durable option for high-stress areas.

- ABS: This material is excellent for impact helmets as it is more heat resistant than PLA and stronger.

- PETG: This material is equally valid for cosplay and safety helmets because of its flexibility and durability.

- Resin (for SLA printers): Even though it is more brittle than FDM materials, SLA resin offers excellent detail and accuracy for intricate works.

Speed and Time for Printing

3D printing a helmet can be a time-consuming exercise, with full-sized helmets taking from 30 to over 100 hours to complete, depending on the printer. If you wish to create more than one, or you have a deadline to meet, you will have to factor in the time you will be spending on printing. If you want the best detail, you can always go for higher-quality settings, but this will increase the time it takes to print.

Summary of the best 3D printers for helmet making

There is a plethora of printers available, making it more challenging to find the best ones for helmet making. Let’s take a look at the best FDM and SLA printers first.

FDM Printers for Helmet Printing

Creality Ender 3 V2

- Best for: Budget-friendly novices

- Pros: Inexpensive, large community, user-friendly

- Cons: Narrow material range, slower throughput

Why it’s excellent for helmets: The Ender 3 V2 is suitable for hobbyists who want to experiment without overspending. Its large print volume and smooth finishes make it an excellent fit for cosplay helmet fabrication.

Prusa i3 MK3S+

- Best for: Accuracy and dependability

- Pros: Great print resolution, material range, and customization options

- Cons: Higher price point

Why it’s great for helmets: This printer is known for dependability and excellent print quality, so it is well-suited for detailed and durable helmet designs.

SLA Printers for Helmet Printing

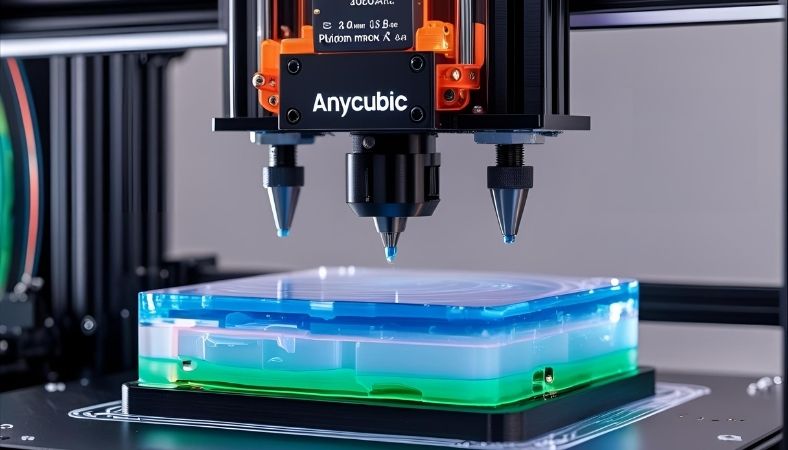

Anycubic Photon Mono X

- Best for: Detailed, smooth finishes on intricate helmets

- Pros: Superb resolution, fast print times, inexpensive resin options

- Cons: Small build volume and more intensive post-processing

Why it’s excellent for helmets: The Photon Mono X is great for intricately detailed, smaller helmet components like faceplates and visors. However, it is not well-suited for larger helmets unless printed in sections.

Hybrid and Other Advanced Printers

Hybrid and Other Advanced Printers

Sovol SV08 MAX

- Best For: Printing helmets at scale.

- Pros: Excellent performance and large print volume.

- Cons: Difficult to calibrate and more expensive than FDM printers.

Why it is unique: The SV08 MAX boasts an impressive print area and can construct helmets in one piece, minimizing the need for post-processing assembly. Enthusiasts who need to print oversized components will find this printer most beneficial.

FDM vs. SLA: Which is better for helmet printing?

Having examined the printers, let us now analyse the two most common 3D printing techniques for helmet manufacturing: FDM and SLA.

Print Quality and Precision

While FDM printers offer the advantage of being able to print larger objects, the layer lines which result from the printing process are usually quite prominent. This is the opposite of what most helmet manufacturers want to achieve. SLA printers excel at creating ultra-smooth and finely detailed prints, making this method more suitable for smaller, more detailed geometries, such as ornaments on a helmet.

Material Versatility

The range of materials includes PLA, ABS, and PETG for FDM printers, while SLA printers are limited to resins. While SLA resins are detailed, they are not as flexible as FDM materials and are not well suited for durable helmets.

Post-Processing Challenges

Both technologies require some form of post-processing, but SLA prints typically require more. SLA printed parts need to be cleaned and cured post-processing, which is more difficult for larger helmets. FDM prints are easier to post-process but may require more sanding to smooth the finish.

Real-World Examples: How 3D Printing Transforms Helmet Production

Let’s examine two 3D-printed helmets to see how 3D printing is transforming helmet production.

Cosplay Helmet Creation

Take a look at the example of a helmet crafted by an avid cosplayer who portrays a customised Stormtrooper. The entire helmet can be printed in parts using an FDM printer like the Creality Ender 3 V2, which is both cost-effective and time-efficient. The printed pieces can then be easily integrated into a seamless, polished appearance through the extensive sanding and painting that the user is willing to do.

For elaborate sections like the helmet’s visor or the intricate internal components, an SLA printer, such as the Anycubic Photon Mono X, is more suited. The SLA printer’s accuracy and attention to detail provided the helmet with a level of authenticity that FDM printers alone could never achieve.

Customization of Motorcycle Helmets

Even motorcycle riders are now using 3D printing technology to design personalised helmets that enhance aerodynamics, comfort, and aesthetics. With the Sovol SV08 MAX, one such rider was able to print a full-sized helmet within days, as the machine’s large build volume permitted a single, integrated design.

Solving Common Problems with 3D Printed Helmets

Efficiency In Time and Material Work

Considering time and material usage is one of the primary concerns when printing helmets in 3D. With larger helmets, the print time alone can reach upwards of 100 hours, and so careful attention to the design is of utmost importance. Time can be saved through the use of lower layer heights, and material usage through adjusting infill percentage.

Challenges Engendered in Post-Processing

Post-processing procedures on 3D-printed helmets come with their challenges. During helmet post-processing, it may be necessary to perform sanding in addition to painting to achieve a smooth surface. Any layer lines should be coated with several layers of primer, and fine-grade sandpaper should be used to smooth out layer lines. Furthermore, paint will be better protected if a clear coating is used.

Considerations Regarding Expenses

An expense of over $200 is incurred during the 3D printing of the helmet. An entry-level printer goes at a bargain price of $200, but a good condition FDM or SLA printer can demand an exorbitant price of $500 to $1500 and sometimes even higher. Expenses of payment for the materials to be used, such as filaments or resin, will also be incurred. If you are looking to reduce your spending, you can revert to cheaper methods, such as printing out helmet parts and using your design to minimise material waste.

3D Printing Your Helmet: Useful Suggestions

Design optimisation, such as helmet design preparation for it to be 3D printed, can be accomplished using programs such as Tinkercad and Fusion 360. Also, remember to include support structures and do not include features that lead to overhangs, as they may create problems during printing.

When it comes to setting the 3D printer, settings in layer height, print speed and temperature should be in the realm of best. Higher-grade filaments should be used to print helmets, ensuring they are of good quality, and finer details are achieved by slowing the printer speed.

Post-Processing Suggestions: Your helmet requires some post-printing processes. Care for your helmet by meticulously sanding and overhauling it with paints and primers so that it looks as if it has been manufactured professionally.

Conclusion: Commence Helmet Printing Projects Today

For your 3D printer and helmet, which one you purchase would depend on whether you are working on an elaborate cosplay helmet or motorcycle headgear. By keeping in mind parameters like print size, material compatibility, and print quality, you are able to keep your helmet project on track.

Eager to get started with 3D printing? If it is an FDM printer you are considering, the Creality Ender 3 V2 would be a good choice, and for SLA, the Anycubic Photon Mono X is also great. These and many more would help you realize your imagination. Happy printing!